This established technological innovation utilizes distinctive rotating tube holders to attach dry- or liquid-filled TPE tubing and assures whole containment of approach fluids by reconnecting discarded tube finishes. Validation protocols make sure Biowelder® TC connections are sterile.

Overview and talk about the historic sterility positive results within the similar products or filling line For the reason that last successful media simulation.

Inspectors needs to have documented teaching for the whole process of transferring and analysis with the sample in the ultimate obvious container. Very low and significant turbidity contamination shall be A part of this teaching.

I have heard of double-toughness media. Does that make it possible for me to implement drinking water to dilute it mainly because it's double-power?

Preferably, media-fill models are inspected and "examine" by a person besides the one that prepared them. The has to be visually inspected on no below day 7 and the end of working day 14, even so we strongly advise that they are go through everyday.

Materials to generally be used from the DCCA with the prepared techniques are amassed then decontaminated by wiping or spraying the outer surface area with IPA or eliminating the outer wrap at the sting of the DCCA because the item is launched in the aseptic do the job region.

from a few consecutive batches advancement is noticed only in a single unit in second batch than what actions must website be taken??

A method for establishing the capability of an aseptic method as carried out utilizing a growth medium in place of the usually filled substance. Observe that APS is comprehended to be synonymous with media fill Test.

I would love to join newsletters from Sartorius (Sartorius AG and its affiliated firms) centered of my personal passions.

Simulating plan device parts assembling/ disassembling, gear/ system setups, in between slight maintenance Employment

This guideline involves guidance for the Microbiology laboratory and environmental checking Section activities for the duration of First and plan semi-annual aseptic method simulations (media fill Test) for new and present goods and procedures.

Actual physical Inspection Finished CSPs are individually inspected in accordance with penned processes after compounding. Otherwise dispersed immediately, these products are separately inspected just prior to leaving the storage spot. Those people products that will not be immediately dispersed are stored within an correct location as described inside the written processes. Immediately just after compounding and as being a problem of release, Just about every products device, where achievable, really should be inspected versus lighted white or black background or both for evidence of obvious particulates or other overseas make any difference.

Minimal-Danger Situations— The CSPs are compounded with aseptic manipulations entirely in just ISO Class five (see Table one) or greater air good quality check here utilizing only sterile substances, goods, factors, and units. The compounding involves only transfer, measuring, and mixing manipulations with closed or sealed packaging techniques which can be carried out instantly and attentively. Manipulations are limited to aseptically opening ampuls, penetrating sterile stoppers on vials with sterile needles and syringes, and transferring sterile liquids in sterile syringes to sterile administration equipment and deals of other sterile merchandise.

Frequently, provides necessary to the scheduled operations of your change are well prepared and introduced to the buffer or cleanse region, if possible on a number of movable carts. Supplies which have been essential for back again-up or general assistance of functions can be saved on the designated shelving while in the buffer or cleanse region, but prevent too much accumulation of materials.

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Samantha Fox Then & Now!

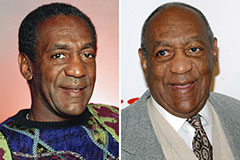

Samantha Fox Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!